NON-CONTACT OPTICAL INCREMENTAL ENCODER

WITHOUT MECHANICAL PARTS

SPEEDWAGON

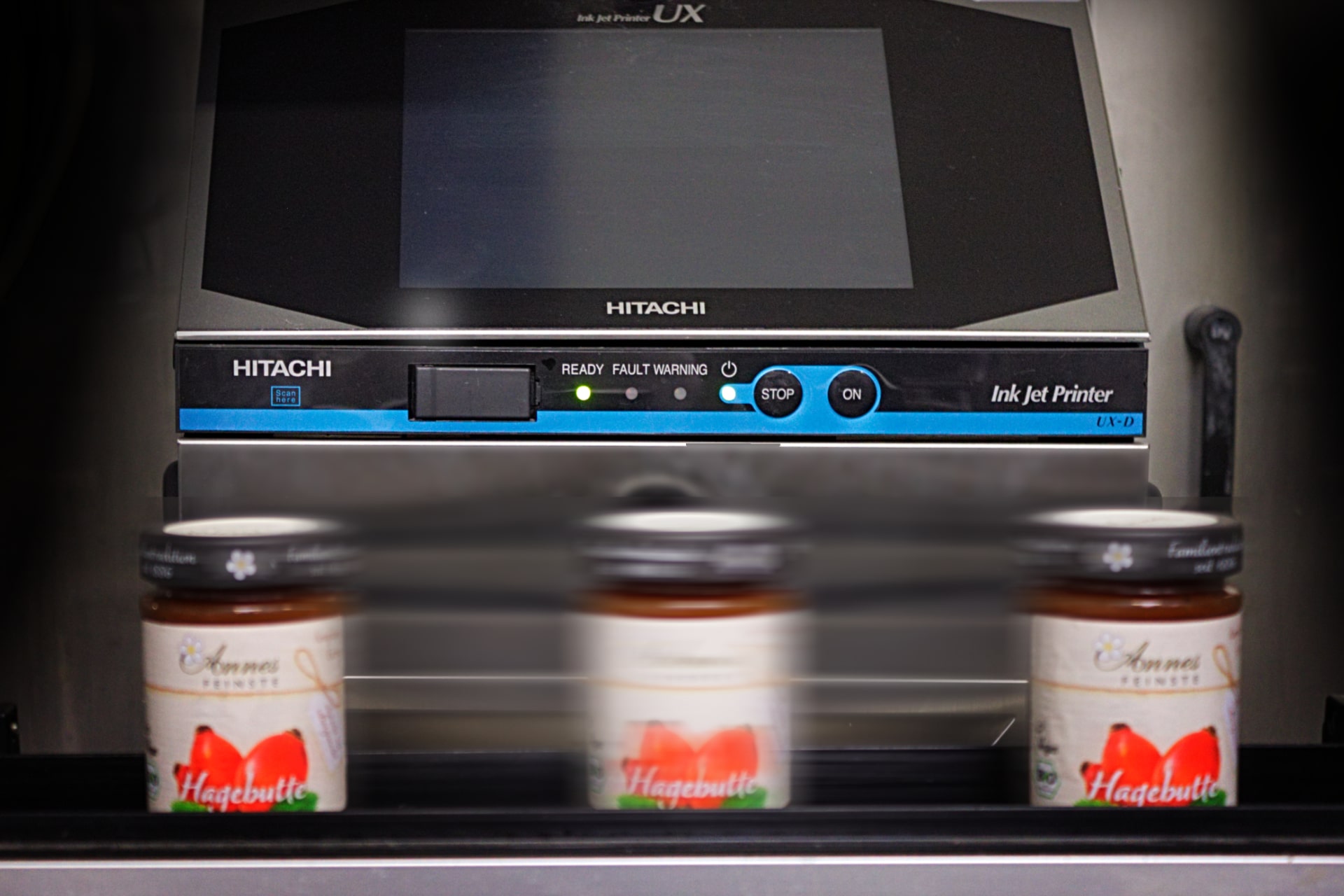

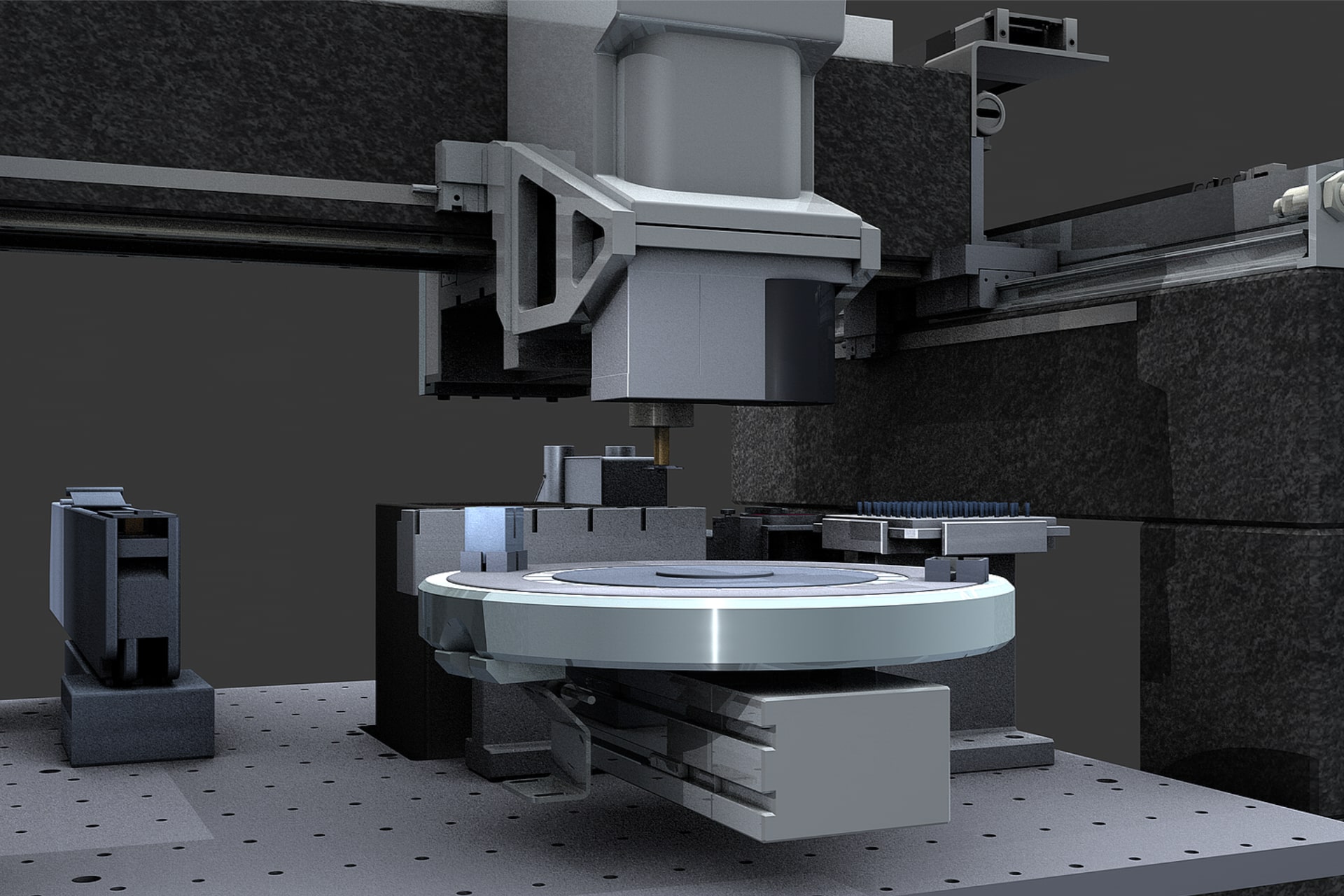

Speedwagon measures the speeds of moving tracks and piece goods in order to monitor, control and regulate production systems. The big advantage: The measurement is non-contact, purely optical, without mechanical components and therefore slip-free. In contrast to measuring wheels and other mechanical processes, Speedwagon achieves a higher measuring accuracy and does not damage the material through mechanical wear. In addition, the system is able to take over a trigger function, i.e. a start pulse for example as an output for marking devices as soon as a previously defined increment value has been reached.

Speedwagon - the wear-free solution for optical measurement

Speedwagon is suitable for almost all materials and surfaces, regardless of whether you are producing soft or moist products - the optical measurement is even excellent for reflective and smooth surfaces. The operation is intuitive.

HIGHLIGHTS

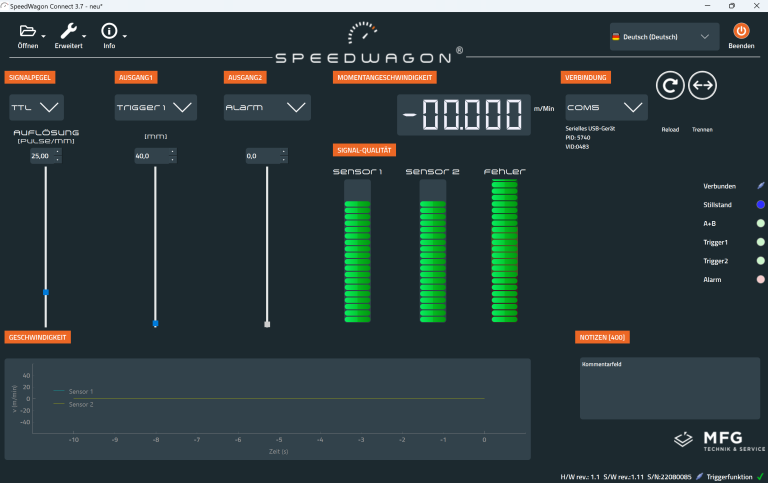

Adjustable encoder output A/B up to 120 pulses/mm

Reverse lock A/B channel for products moving backwards temporarily

Input correction factor for adjusting exact distances

Two freely programmable trigger outputs push/pull, NPN and PNP output with reversible signal level

Trigger and sequential trigger up to 6500 mm distance

Trigger block for freely adjustable distance

Standstill threshold (start/stop threshold) to filter out, for example, startup/shutdown ramps when starting up products (foils, etc.) and micro-vibrations in the movement pattern of products

Output for signal reversal on change of direction (traversing axes)

Two mutually monitoring sensors (failure, contamination)

FUNCTION

Speedwagon is mounted above/at a position where it can scan the surface of the products or materials. For example, on a rotating shaft, on a moving conveyor belt, on moving objects (continuous foils, cardboard boxes, plates, packaging, etc.).

Since Speedwagon not only works contact-free, i.e. purely optically, but also without mechanical components, the distance to the surface to be scanned is also variable. A maximum distance of 15 - 60 mm is recommended.

Speedwagon "scans" the surface and calculates the detected speed. The determined value can be configured as required so that the speed pulses arrive ideally for the connected device. Integration into existing production lines is simple.

Speed

Speed (maximum):

0.5...135 m/min; 2250 mm/sec

Distance

Working distance: 15...60 mm

Power consumption

100 mA

Accuracy

Measuring accuracy: +/- 0.3%

Protection class

Protection class: IP67

Surfaces

Measuring surfaces – all, including glass and reflective surfaces

Interface

Encoder A & B

Out 1: Trigger 1

Out 2: optional

Trigger 2, Direction, Error

Voltage

Laser class

Laser class: 1

TECHNICAL

The use of Speedwagon on various production lines is diverse: packaging machines, paper machines, Fourdrinier machines, slitter rewinders, winding machines, laminating machines, extrusion lines, coating machines, rolling mills, etc.

Speedwagon is suitable for almost all materials:

- Cardboard, paper

- Glass, film, foil, plastic

- Textiles, fabrics

- Metal, cable, wire

- Hoses, profiles

- Rolled material, strips, sheets

FEATURES

Speedwagon offers many advantages over mechanical solutions and

is cheaper than laser-controlled devices:

Technical functions

- Non-contact measurement of speeds and lengths

- Trigger function

- Accuracy: resolution at 60 pixels/mm

- Slip-free

- Several printers/devices can be controlled in parallel

- Frequency of the output signal can be selected as desired

- All materials

Operation and maintenance

- Simple process integration

- Robust

- Ex-protected

- Print image can be optimally adjusted thanks to the programming functions (inkjet)

- Error output if optics dirty

- Intuitive programming, integration and connectivity

- Plug and Play with all systems

- Standstill and direction detection scannable (also glass and highly reflective materials)

ECONOMY

- Cost-effective

- Can be directly integrated into a device (e.g. HP cartridge printer)

- Suitable for industry, very compact

- Several printers/devices can be controlled in parallel

- Low power consumption

- Direct connection to the printing device, no external power pack required

LIVE OPERATION

Speedwagon is used everywhere in the industrial sector to measure and transmit speeds on systems and machines. Speedwagon helps to adjust writing speeds of marking systems or to synchronize work steps/cycles of a machine, to measure lengths, to start and control machine cycles, etc.

BRANCHES

Speedwagon is suitable for almost all industries.

The fields of application are limitless.

Beverages/Food

Mechanical engineering, automotive

Pharma

Electric

Logistics

SOFTWARE

Speedwagon "Connect" operating software - intuitive and stylish.

LIVE OPERATION

Contactless

Measure speeds of

webs

FUTURE INDUSTRIAL MANUFACTURING

I am convinced that non-contact optical scanning without mechanical parts will become established in speed and length measurement in the next few years.

Hubert lachner

OWNER/MANAGING DIRECTOR

ART OF REDUCTION

"Two of my mantras have always been - focus and simplicity. Simple can be more difficult than complex."

Steve Jobs

SPEEDWAGON

- MFG Technology & Service GmbH

- Am Amperkanal 2

- 85402 Kranzberg

- T. +49 8166 99 340 - 0

- info@speedwagon-sensors.com